Crashworthiness, a critical automotive safety factor, is significantly enhanced by High-Strength Steel (HSS) panels integrated into vehicle body structures. HSS panels offer superior tensile strength and improved ductility compared to traditional steels, enabling them to absorb and distribute crash energy effectively during collisions. This structural integrity reduction minimizes passenger injury risk and simplifies post-accident auto painting repairs. Strategically placed in critical areas like fenders and frames, HSS panels are lightweight, fuel-efficient, readily available, cost-effective, and undergo rigorous testing for safety compliance, making them a preferred choice for automakers and car repair projects.

In today’s automotive landscape, crashworthiness is paramount. High-strength steel (HSS) panels are revolutionizing vehicle safety by enhancing structural integrity and energy absorption during collisions. This article delves into the critical role of understanding crashworthiness in automotive design and explores the unique properties and advantages of HSS panels. We examine their integration and testing, demonstrating how these advanced materials improve overall crash performance, setting new standards for passenger protection.

- Understanding Crashworthiness and Its Importance in Automotive Design

- High-Strength Steel Panels: Properties and Advantages for Vehicle Safety

- Integration and Testing: How High-Strength Steel Panels Enhance Crash Performance

Understanding Crashworthiness and Its Importance in Automotive Design

Crashworthiness, a critical aspect of automotive design, refers to a vehicle’s ability to protect occupants and minimize injury during a collision. It involves the structural integrity of the vehicle, ensuring that it absorbs and distributes crash energy effectively while maintaining passenger safety. In today’s world, where high-strength steel panels are increasingly being integrated into auto body work, understanding crashworthiness has become more vital than ever. These advanced materials play a pivotal role in enhancing a vehicle’s overall safety performance.

The importance of crashworthy design cannot be overstated, especially with the rising demand for safer vehicles. High-strength steel, known for its superior tensile strength and durability, offers automotive engineers a powerful tool to combat the challenges posed by modern traffic accidents. By employing these panels in various auto body services, manufacturers can create more robust structures that better withstand impact, thereby reducing the risk of severe injuries during crashes. This, in turn, not only enhances passenger safety but also reduces the need for extensive and costly auto painting repairs post-accidents.

High-Strength Steel Panels: Properties and Advantages for Vehicle Safety

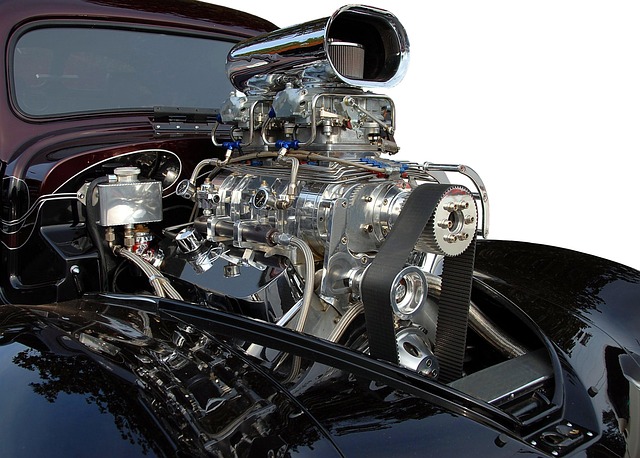

High-Strength steel panels have revolutionized vehicle safety and crashworthiness. Unlike traditional steel, which offers good strength but limited flexibility, high-strength steel combines exceptional tensile strength with improved ductility. This unique blend allows these panels to withstand significant impact energy during a collision, absorbing and distributing it across a larger area. The result is enhanced structural integrity, reducing the risk of vehicle intrusion and protecting occupants from severe injuries.

These panels’ advantages extend beyond their inherent strength. They are lightweight compared to alternative materials like aluminum, enabling better fuel efficiency without compromising safety. Moreover, high-strength steel is readily available and cost-effective, making it a viable option for automakers seeking to enhance vehicle safety without significantly impacting production costs. This feature also makes these panels suitable for various car repair services and even car restoration projects, where strength and durability are paramount.

Integration and Testing: How High-Strength Steel Panels Enhance Crash Performance

High-Strength Steel Panels (HSSP) play a pivotal role in enhancing vehicle crashworthiness by significantly improving structural integrity during collisions. These panels, designed to withstand extreme forces, are strategically incorporated into various body components, including fenders and frames. Their superior strength allows for better energy absorption, reducing the impact on the overall structure of the vehicle.

Integration of HSSP involves rigorous testing to ensure their compatibility with existing designs while maintaining safety standards. Crash tests, for instance, are conducted to simulate real-world scenarios, enabling engineers to assess the performance of these panels under various conditions. Through such testing, manufacturers can optimize panel placement, ensuring optimal crash performance without compromising on lightweight properties or structural rigidity, thereby fostering efficient collision center operations and facilitating effective fender repair processes.

High-strength steel panels have emerged as a game-changer in automotive design, significantly enhancing vehicle crashworthiness. Their unique properties and advantages, discussed in this article, include improved strength-to-weight ratios, better energy absorption, and reduced weight, all of which contribute to safer vehicles. Through integration and rigorous testing, these panels prove their worth by offering superior protection in collisions, ensuring that modern cars can withstand harsh impacts while protecting occupants effectively. This shift towards high-strength steel panels marks a pivotal step forward in the continuous pursuit of safer automotive technologies.