High-strength steel panels offer unparalleled durability, impact resistance, and weight reduction capabilities, making them ideal for automotive manufacturing and premium vehicle repairs like Mercedes Benz. While aluminum panels provide lightweight construction, corrosion resistance, and environmental benefits, they have lower tensile strength and structural integrity compared to high-strength steel, which retains superior weldability and resistance to extreme loads.

In the realm of construction and automotive industries, the choice between high-strength steel panels and aluminum panels is a key decision. This article delves into the intricacies of these two materials, offering a comprehensive guide for understanding their unique properties. We explore the advantages of high-strength steel panels, such as superior strength-to-weight ratio and enhanced durability, while also examining the benefits and limitations of aluminum. The comparative analysis reveals optimal applications for each, providing insights to navigate this essential choice.

- Understanding High-Strength Steel Panels: Properties and Advantages

- Aluminum Panels: Weighing the Benefits and Limitations

- Comparative Analysis: High-Strength Steel vs Aluminum for Various Applications

Understanding High-Strength Steel Panels: Properties and Advantages

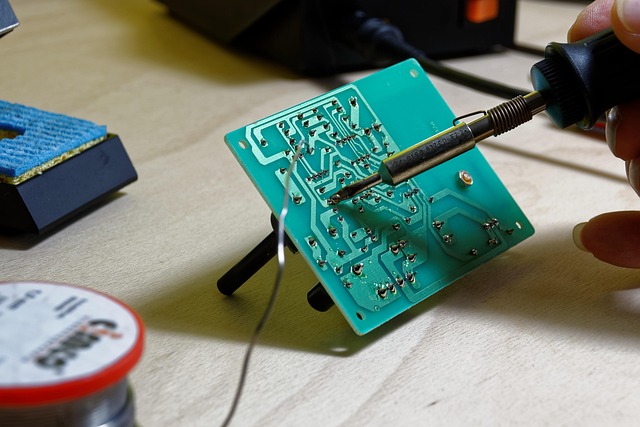

High-strength steel panels are a revolutionary advancement in the automotive industry, offering exceptional durability and performance. These panels, as the name suggests, possess superior mechanical properties, making them ideal for demanding applications. With a focus on enhancing structural integrity, high-strength steel is known for its excellent resistance to deformation and impact, ensuring the safety and reliability of vehicles. This material’s unique composition allows it to retain strength even under extreme conditions, which is a significant advantage in various industries, including auto repair shops and auto body shops.

One of the key benefits of using high-strength steel panels is their ability to reduce weight without compromising strength. In the case of vehicle manufacturing, this translates to improved fuel efficiency and reduced carbon emissions, aligning with modern environmental standards. Moreover, these steel panels offer excellent corrosion resistance, ensuring longevity in various weather conditions. When compared to traditional aluminum panels, high-strength steel provides a more robust solution, making it a preferred choice for premium vehicles like Mercedes Benz repair applications, where performance and durability are paramount.

Aluminum Panels: Weighing the Benefits and Limitations

Aluminum panels have long been a popular choice for vehicle repair and auto collision centers due to their light weight and corrosion resistance. These benefits make them particularly appealing for car collision repair, as they can help reduce overall vehicle weight, enhancing fuel efficiency and handling. Additionally, aluminum is non-reactive, ensuring that it won’t rust or corrode in moist environments, a significant advantage over traditional metal panels.

However, there are limitations to using aluminum panels. They have lower tensile strength compared to high-strength steel panels, which can be a concern for structural integrity in certain applications. Aluminum also has a lower resistance to impact and denting, making it more susceptible to damage during accidents or harsh weather conditions. Furthermore, while aluminum is recyclable, the process can be energy-intensive, unlike steel, which is inherently more sustainable.

Comparative Analysis: High-Strength Steel vs Aluminum for Various Applications

In a head-to-head comparison, high-strength steel panels and aluminum sheets find their unique advantages in various applications. High-strength steel excels in demanding sectors such as construction and automotive industries, offering superior strength and durability. Its robust nature makes it ideal for structural elements, especially in buildings and bridges where resistance to extreme loads is paramount. Furthermore, the metal’s excellent weldability facilitates intricate designs and complex fabrication processes, a benefit evident in modern vehicle bodywork and car body shops.

Aluminum panels, on the other hand, have revolutionized paintless dent repair and light-weight vehicle construction. Its remarkable corrosion resistance makes it a top choice for outdoor structures and automotive components exposed to harsh weather conditions. Aluminum’s low density contributes to fuel efficiency in vehicles, making it an attractive option for environmentally conscious manufacturers. In addition, its excellent conductivity of heat and electricity opens doors for innovative applications beyond traditional bodywork, such as in electrical equipment and industrial machinery.

When considering materials for construction or automotive applications, high-strength steel panels offer exceptional durability and strength while being cost-effective. Their superior properties make them a game-changer in industries seeking robust solutions. While aluminum panels have their merits, high-strength steel is often the preferred choice for demanding projects due to its ability to withstand extreme conditions without compromising structural integrity. This comprehensive analysis highlights the value of high-strength steel panels as a reliable and versatile option for various applications.